What Is Noise-Induced Hearing Loss?

Noise-induced hearing loss (NIHL) isn’t something you wake up with one day. It creeps in slowly, like rust on metal. You start missing parts of conversations, turn the TV up too loud, or keep asking people to repeat themselves. By the time you notice, the damage is already done-and it’s permanent. Unlike a broken bone or a cut that heals, the tiny hair cells in your inner ear that pick up sound never grow back. Once they’re destroyed by loud noise, they’re gone for good.

This isn’t just about concerts or headphones turned up too high. The biggest threat comes from jobs. Every day, millions of workers are exposed to noise levels that slowly destroy their hearing. In the U.S., 22 million workers are exposed to dangerous noise at work each year. That’s nearly one in six people in the workforce. And it’s not just factories or construction sites. Farmers, mechanics, warehouse workers, and even some office staff near loud HVAC systems are at risk.

How Loud Is Too Loud?

It’s not just about how loud the noise is-it’s about how long you’re exposed to it. The rule of thumb is simple: if you have to shout to be heard by someone standing an arm’s length away, the noise is already dangerous.

Regulations say 85 decibels (dBA) is the level where hearing protection becomes mandatory. That’s about the noise of heavy city traffic, a lawnmower, or a blender running. But here’s the catch: 85 dBA isn’t safe. It’s the line where hearing loss starts. Dr. Thais Morata from NIOSH puts it plainly: “Occupational noise exposure limits do not prevent NIHL. They’re not safe limits-they’re damage thresholds.”

Every 3-decibel increase doubles the noise energy. That means:

- 85 dBA = 8 hours of exposure = risk begins

- 88 dBA = 4 hours

- 91 dBA = 2 hours

- 94 dBA = 1 hour

- 100 dBA = just 15 minutes

That’s why a jackhammer at 110 dBA can cause damage in under 2 minutes. And in places like mining or metal fabrication, workers are often exposed to 105-115 dBA for hours at a time.

Why Most Hearing Protection Fails

Companies give out foam earplugs. Workers get them in their ears. That’s the end of the story for many employers. But here’s the problem: 75% of people insert foam earplugs wrong.

Proper insertion requires rolling the plug into a thin cylinder, pulling the ear up and back, and holding it in place for 20-30 seconds until it expands. Most people just shove them in and walk away. Real-world attenuation drops from 30 dB (lab rating) to just 15-20 dB. That’s the difference between protection and no protection at all.

Custom-molded earplugs work better-25-30 dB of consistent attenuation-but they’re expensive and not always provided. Earmuffs help, but they’re bulky, hot, and often removed because workers can’t hear warnings or talk to coworkers. A Reddit user in construction wrote: “Most guys take their earplugs out because they can’t hear equipment warnings or coworkers. Management gives us cheap foam plugs that hurt after two hours.”

NIOSH’s 2021 data shows only 38% of workers in high-noise jobs wear protection the whole shift. Why? Discomfort. Communication issues. And the false belief that “I’ve been here 10 years and I’m fine.” But hearing loss doesn’t show up overnight. It’s cumulative. You don’t notice it until it’s too late.

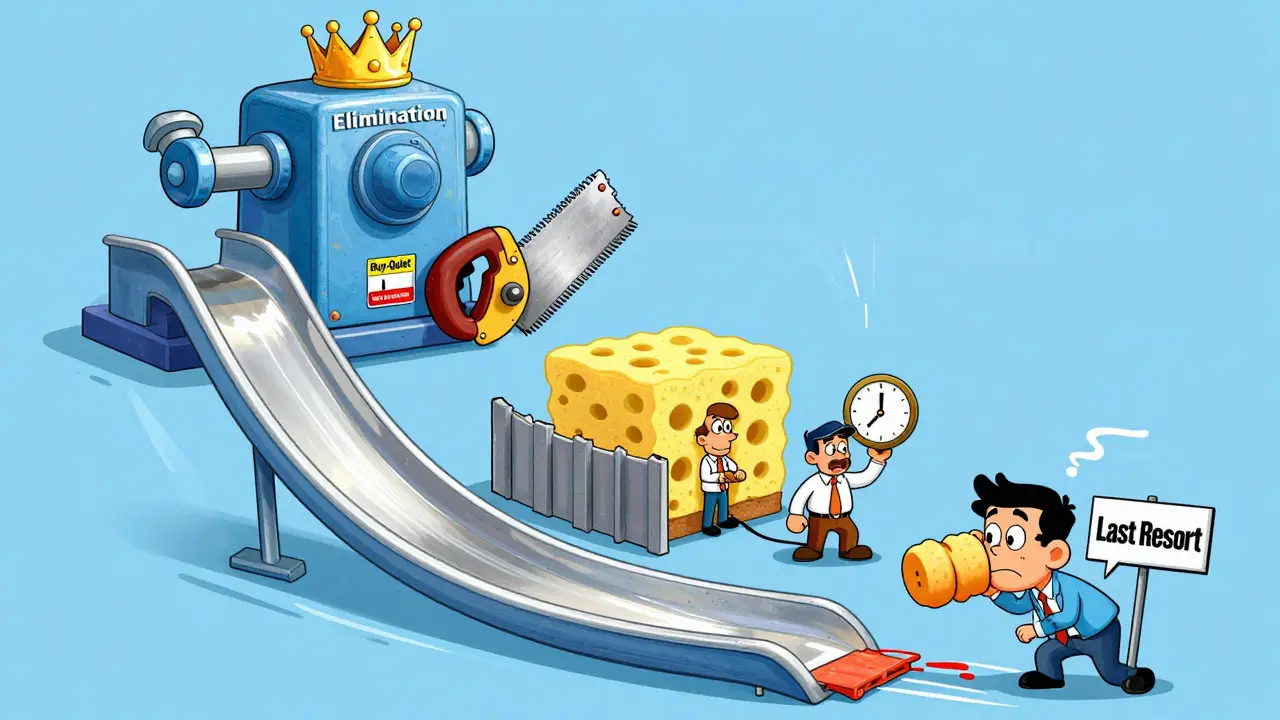

What Actually Works: The Hierarchy of Controls

There’s a proven way to stop NIHL before it starts. It’s called the hierarchy of controls-and it’s not about earplugs. Earplugs are the last resort.

Here’s how it works, from most to least effective:

- Elimination: Remove the noise source. Can you replace that old, noisy compressor with a newer, quieter model? This is the gold standard.

- Substitution: Swap noisy equipment for quieter alternatives. NIOSH’s “Buy-Quiet” initiative now lists over 1,200 low-noise machines. A 5-15 dBA reduction can cut exposure time by half or more.

- Engineering Controls: Install barriers, enclosures, or vibration dampeners. In one mining case, noise dropped from 98 dBA to 82 dBA after adding acoustic panels around drills. Workers reported less fatigue and better focus.

- Administrative Controls: Rotate workers, limit time in noisy areas, schedule loud tasks for low-traffic hours. But these are unreliable-effectiveness varies by 25-75% depending on how well they’re managed.

- Hearing Protection Devices (HPDs): Earplugs and earmuffs. Only effective if properly fitted, consistently worn, and regularly checked.

Yet, most companies stop at step five. Why? Because fixing machines or buying new equipment costs money. Giving out earplugs doesn’t.

What Employers Are Required to Do (and What They Usually Skip)

OSHA requires hearing conservation programs when noise hits 85 dBA over 8 hours. That means:

- Annual audiometric testing (hearing checks)

- Training on noise risks and proper use of earplugs

- Providing hearing protection

- Keeping exposure records

But here’s what most companies miss:

- Baseline hearing tests must be done within 6 months of starting the job. Many wait a year-or longer.

- Testing must use calibrated equipment at frequencies from 500 to 6000 Hz. Many clinics skip 3000-6000 Hz, missing early signs of damage.

- A “standard threshold shift” (STS) is defined as a 10 dB drop at 2000, 3000, and 4000 Hz compared to baseline. If this happens, the employer must notify the worker and re-evaluate controls. But many don’t track this properly.

OSHA’s 2022 enforcement data shows only 49% of manufacturing plants fully comply. And in high-risk industries like construction and agriculture, NIHL rates are 30% higher than average. That’s not an accident. It’s negligence.

How to Know If Your Hearing Is Already Damaged

NIHL doesn’t hurt. It doesn’t make your ears ring right away. It’s silent. The first sign is usually difficulty understanding speech in noisy places-like a restaurant or a crowded room. You hear people talking, but the words get lost.

Other signs:

- Needing to turn up the TV or radio louder than others

- Thinking people are mumbling

- Difficulty hearing high-pitched sounds (birds, children’s voices, doorbells)

- Tinnitus (ringing, buzzing, or hissing in the ears)-often the earliest warning sign

If you’ve worked in a noisy job for more than 5 years and notice any of these, get a hearing test. Don’t wait. Audiometric testing is free for workers under OSHA rules. Use it.

What’s Changing in 2025

The old rules aren’t working. A 2024 Nature study confirmed: “Occupational noise exposure limits do not prevent NIHL.”

NIOSH is pushing for a new recommended limit of 80 dBA by 2025-half the energy allowed under OSHA’s 90 dBA rule. That’s a 16-fold reduction in allowable noise exposure. California already moved ahead, requiring employers to try engineering controls before relying on earplugs.

Technology is catching up, too. New smart earplugs like 3M’s PELTOR TS3+ record your daily noise exposure and sync with apps for compliance tracking. Researchers at USC are testing blood biomarkers to detect early cell damage before it shows up on a hearing test.

But the biggest change isn’t technical. It’s cultural. Companies that succeed in preventing NIHL don’t just hand out earplugs. They involve workers in choosing equipment, give them real training, and make hearing protection part of daily safety culture.

What You Can Do Right Now

If you’re exposed to loud noise at work:

- Ask for a hearing test if you haven’t had one in the last year.

- Don’t assume your earplugs are working. Ask your safety officer for a fit test (Real Ear Attenuation at Threshold or REAT). It takes 5 minutes and tells you if your plugs are actually protecting you.

- Report noisy equipment. If a machine is louder than others like it, it might be broken. Fixing it helps everyone.

- Wear protection consistently-even if you think you’re fine. Damage adds up.

- Use the NIOSH Sound Level Meter app (free on iOS) to check noise levels around you. It’s accurate to ±2 dB.

If you’re a manager or safety officer:

- Stop treating hearing protection as the solution. Start treating noise reduction as the goal.

- Invest in Buy-Quiet equipment. A $5,000 quieter saw saves $14,700 in workers’ comp per hearing loss claim.

- Train workers on earplug insertion. Use a mirror. Make them practice. 75% get it wrong the first time.

- Track audiometric results. If you see a threshold shift, act-not just on the worker, but on the source of the noise.

- Ask workers what’s stopping them from wearing protection. Listen. Then fix it.

Noise-induced hearing loss is the second most common occupational illness in the U.S. But here’s the truth: it’s 100% preventable. Not 90%. Not 80%. 100%. You don’t need magic. You just need to care enough to do the right thing.

Frequently Asked Questions

Can noise-induced hearing loss be reversed?

No. Once the hair cells in your inner ear are damaged by loud noise, they don’t regenerate. The hearing loss is permanent. That’s why prevention is the only effective strategy. No medicine, surgery, or device can restore lost hearing from noise exposure.

Are earplugs enough to protect my hearing at work?

Not by themselves. Earplugs are the last line of defense. If noise levels are above 85 dBA, you need engineering controls-like quieter machines, sound barriers, or enclosures-to reduce the noise at the source. Earplugs often fail because they’re inserted wrong, removed too often, or don’t fit well. Even the best earplugs only work if worn correctly and consistently.

What’s the difference between OSHA and NIOSH noise limits?

OSHA allows up to 90 dBA over 8 hours with a 5-dB exchange rate (doubling exposure time for every 5 dB increase). NIOSH recommends 85 dBA with a 3-dB exchange rate, meaning exposure time cuts in half for every 3 dB increase. NIOSH’s limit is much stricter-allowing only 1/16th the noise energy of OSHA’s. NIOSH’s standard is based on preventing hearing loss, while OSHA’s is based on what’s legally enforceable.

How often should I get my hearing tested at work?

You should get a baseline hearing test within 6 months of starting a job with noise exposure above 85 dBA. After that, annual tests are required by OSHA. If your hearing test shows a “standard threshold shift” (a 10 dB drop at key frequencies), your employer must investigate the cause and take action.

What jobs carry the highest risk of noise-induced hearing loss?

Construction, manufacturing, mining, and agriculture have the highest rates. In construction, 22% of workers are exposed to noise above 85 dBA. In mining, it’s 17%. Even jobs like auto repair, woodworking, and airport ground crew face high risks. Any job involving power tools, heavy machinery, or loud engines puts you at risk.

Is tinnitus a sign of noise-induced hearing loss?

Yes. Tinnitus-ringing, buzzing, or hissing in the ears-is often the earliest warning sign of noise damage. It can appear before hearing loss shows up on a test. If you experience tinnitus after work, especially if it lasts more than a few hours, it’s a red flag. Don’t ignore it. Get your hearing checked.

Health and Wellness

Health and Wellness

Lisa Davies

December 15, 2025 AT 07:33Cassie Henriques

December 16, 2025 AT 15:49Raj Kumar

December 16, 2025 AT 19:58RONALD Randolph

December 18, 2025 AT 07:05Benjamin Glover

December 19, 2025 AT 15:23Michelle M

December 21, 2025 AT 11:45Jake Sinatra

December 22, 2025 AT 01:17Melissa Taylor

December 22, 2025 AT 08:06John Brown

December 22, 2025 AT 21:27Nupur Vimal

December 24, 2025 AT 03:56